Plastic auto parts play a crucial role in enhancing your vehicle’s fuel efficiency. By significantly reducing weight, these components improve overall vehicle dynamics. For instance, every 45 kg of weight reduction can increase energy efficiency by 2%. This means that switching to plastic parts not only lightens your car but also leads to remarkable fuel savings. Additionally, when combined with components like a stainless steel U-shaped heating tube, the overall performance and efficiency of your vehicle can be further optimized.

Key Takeaways

- Switching to plastic auto parts can significantly reduce vehicle weight, leading to improved fuel efficiency and performance.

- Plastic components offer design flexibility, allowing for better aerodynamics that enhance vehicle dynamics and reduce fuel consumption.

- Investing in plastic auto parts not only lowers manufacturing costs but also results in long-term savings on fuel expenses.

Weight Reduction Benefits

Impact on Vehicle Dynamics

When you reduce the weight of your vehicle by incorporating plastic auto parts, you significantly enhance its dynamics. A lighter vehicle accelerates faster and stops more quickly. Here are some key benefits of weight reduction on vehicle performance:

- Faster Acceleration: Lighter vehicles require less energy to gain speed. This means you can enjoy a more responsive driving experience.

- Improved Braking: With reduced mass, your vehicle can stop more efficiently. This leads to shorter braking distances, enhancing safety.

- Better Handling: A lighter chassis improves overall handling, allowing for better maneuverability on the road.

In essence, the use of plastic auto parts not only contributes to a lighter vehicle but also enhances your driving experience through improved acceleration, braking, and handling.

Correlation with Fuel Economy

The relationship between vehicle weight and fuel consumption is crucial. Heavier vehicles demand more energy to move, which directly impacts fuel efficiency. For instance, research shows that heavier vehicles, like the GMC Sierra 1500, consume more fuel compared to lighter models. This is due to the increased force required for acceleration and maintaining speed.

- Increased Inertia: Heavier vehicles possess greater inertia, requiring more energy to initiate movement. This results in higher fuel consumption.

- Rolling Resistance: Heavier vehicles experience increased rolling resistance, which demands more energy to sustain a constant speed.

Statistical analysis highlights this correlation. Larger vehicles, such as SUVs and pickups, have significantly lower fuel economy compared to smaller cars. On average, larger vehicles consume about 606 gallons of fuel annually, while smaller cars consume around 468 gallons. This stark difference underscores the impact of weight on fuel efficiency.

Moreover, the trend towards incorporating more plastic parts in modern vehicles is driven by the need for lighter designs. Plastic components are approximately 30% lighter than traditional materials like fiberglass. This reduction in weight allows vehicles to consume less energy, ultimately improving their miles per gallon (MPG) ratings. Experts agree that lighter vehicles lead to better fuel economy, making plastic auto parts a smart choice for those seeking higher MPG ratings.

Design Flexibility

Aerodynamics and Efficiency

Plastic auto parts offer remarkable design flexibility that significantly enhances vehicle aerodynamics. This flexibility allows manufacturers to create components that reduce drag and improve fuel efficiency. Here are some key design features that contribute to better aerodynamics:

| Design Feature | Contribution to Aerodynamics |

|---|---|

| Lightweight Properties | Reduces fuel consumption and increases vehicle range. |

| Design Flexibility | Enables easy optimization of aerodynamics and ergonomics through molding into various shapes. |

The exceptional strength-to-weight ratio of plastic materials allows for complex geometries that optimize aerodynamics. These shapes can minimize air resistance, leading to improved fuel efficiency. For instance, the development of thermoplastics and composite materials has resulted in lightweight components that maintain high strength and durability. Such materials withstand extreme conditions, making them ideal for automotive applications where aerodynamics is crucial.

Did You Know? More than 50% of a truck’s fuel is used to overcome aerodynamic drag at highway speeds. By improving aerodynamics, you can achieve significant fuel savings. A combination of devices that enhance truck aerodynamics could reduce fuel consumption by 12%, translating to over $10 billion in diesel fuel savings annually for the trucking industry.

Customization for Performance

Customization is another significant advantage of plastic auto parts. You can tailor these components to meet specific performance needs, enhancing your vehicle’s overall functionality. Here are some examples of how customization can improve performance:

| Application | Material Used | Description |

|---|---|---|

| Piston Rings | PEEK | Used in automatic transmissions for improved performance. |

| Wear Plates | Advanced engineered plastics | Enhances durability in gear systems. |

| EMI/RFI Shields | Engineered plastics | Absorbs vibrations and provides thermal/electrical conductivity. |

Reinforced plastics achieve tight tolerances for strength and safety. Engineered plastics absorb vibrations better than metals, which can lead to a smoother ride. Additionally, custom injection molding allows for tailored designs that enhance vehicle aesthetics while maintaining performance.

The flexibility of plastic materials enables innovative design solutions in automotive engineering. Manufacturers can create intricate shapes that enhance functionality and improve aerodynamics. The lightweight nature of plastics contributes to better fuel efficiency, while aesthetic versatility allows for stylish interiors and diverse style choices.

Cost-Effectiveness

Manufacturing and Material Costs

Switching to plastic auto parts can significantly reduce your manufacturing costs. Here are some key points to consider:

- You can achieve overall cost savings of 25-50% by moving from metal to plastic.

- Plastic parts often require fewer secondary operations and assembly steps, streamlining production.

- Original Equipment Manufacturers (OEMs) can combine multiple components into a single molded part, simplifying the manufacturing process.

For example, an engine hood made of steel typically costs between 300-400 RMB. In contrast, using ABS plastic can lower that cost to just 150-200 RMB. This shift can decrease material costs for individual components by 40-60%. Additionally, plastic raw materials are generally less expensive than metals. Unlike metal prices, which can fluctuate, plastic shortages are rare, providing more predictable costs.

Long-Term Savings on Fuel

Investing in plastic auto parts not only saves you money upfront but also leads to long-term fuel savings. Here’s how:

- Lower material costs and efficient production processes contribute to reduced overall production expenses.

- The lightweight nature of plastic parts enhances fuel efficiency, allowing you to save on fuel costs over time.

- Reduced assembly time and costs further lower your overall expenses, enabling manufacturers to produce more affordable vehicles without sacrificing quality.

By choosing plastic auto parts, you position yourself for significant savings in both manufacturing and fuel costs. This strategic decision not only benefits your wallet but also supports a more sustainable automotive industry.

Real-World Applications

Electric Vehicles and Hybrids

Plastic auto parts play a vital role in enhancing the efficiency of electric vehicles (EVs) and hybrids. The primary reason for using plastics in these vehicles is weight reduction. Lighter vehicles require less energy to operate, which leads to greater range between recharges. Here are some key benefits of plastic components in EVs and hybrids:

- Weight Reduction: The integration of fiber-reinforced thermoplastics helps reduce weight, crucial for balancing the heavy batteries in electric vehicles.

- Fuel Efficiency: Studies show that using plastics can decrease fuel consumption by 0.2 liters per 100 km and lower CO₂ emissions by 10 g/km.

- Sustainability: The shift from metal to plastic supports sustainability efforts while enhancing overall vehicle performance.

For example, the 2025 Toyota Corolla Cross Hybrid utilizes ABS composites for 27 components, achieving a 14.3 kg weight reduction and a 22% increase in rigidity. Independent crash tests showed a 32% increase in energy absorption during impacts, demonstrating the effectiveness of plastic auto parts in real-world driving conditions.

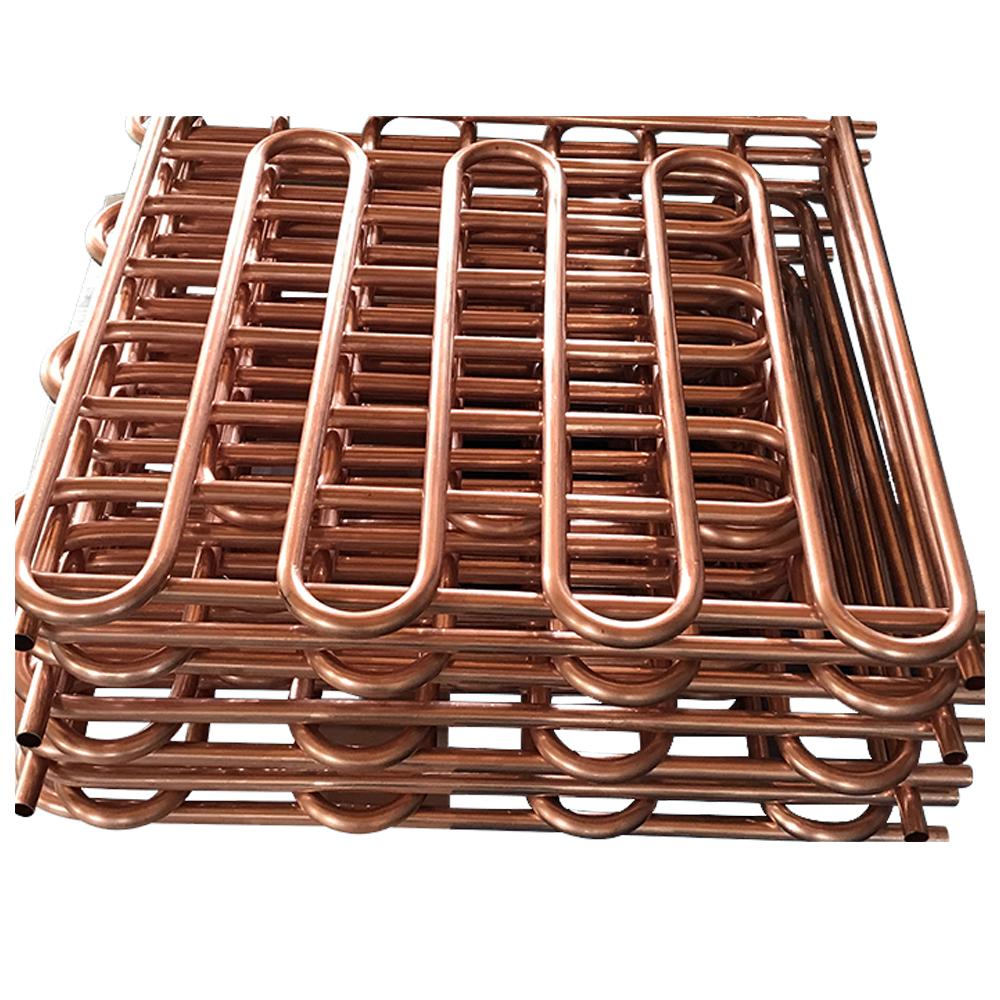

Stainless Steel U-Shaped Heating Tube Integration

Integrating stainless steel U-shaped heating tubes with plastic components presents unique challenges and solutions. One significant challenge is the adhesion between the two materials. To address this, manufacturers apply organosilane surface coatings on stainless steel, resulting in a 32% improvement in lap shear strength for welded joints.

| Challenge | Solution | Result |

|---|---|---|

| Adhesion issues between PPS and stainless steel | Application of organosilane surface coatings on stainless steel | 32% improvement in lap shear strength for welded joints |

This innovative approach not only enhances the durability of the assembly but also contributes to the overall efficiency of the vehicle. By combining the lightweight nature of plastic with the strength of stainless steel, manufacturers can optimize performance while reducing weight.

Adopting plastic auto parts is a viable strategy for enhancing fuel efficiency. You gain significant benefits, including:

- Weight Reduction: Lighter vehicles consume less fuel.

- Design Flexibility: Improved aerodynamics lead to better performance.

- Cost-Effectiveness: Lower manufacturing costs translate to savings.

Remember, using plastics not only boosts efficiency but also supports sustainability efforts in the automotive industry.