Aluminum Extrusion Profiles significantly enhance vehicle efficiency and safety. Their lightweight nature allows vehicles to consume 18% less fuel compared to those made with heavier materials like steel. This reduction in weight leads to improved fuel economy, reduced carbon emissions, and enhanced overall performance. Additionally, aluminum’s structural integrity improves crash performance and offers design flexibility for advanced safety features, making it an ideal choice for components such as the Stainless Steel U-shaped Heating Tube and Hood Latch Flexible Draw Latch.

Key Takeaways

- Aluminum extrusions reduce vehicle weight, leading to 18% better fuel efficiency and lower carbon emissions.

- These extrusions enhance crash safety by absorbing impact energy, protecting passengers during collisions.

- Aluminum’s design flexibility allows for innovative vehicle components, improving both aesthetics and functionality.

Understanding Aluminum Extrusion Profiles

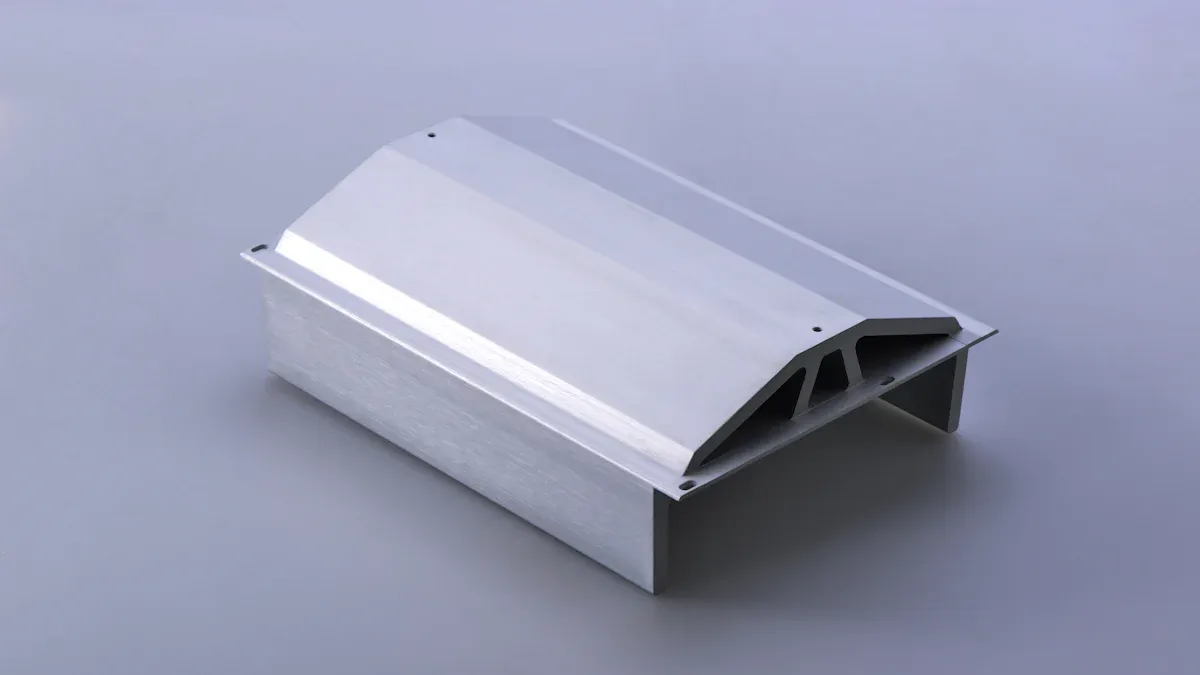

Aluminum extrusion profiles play a vital role in automotive manufacturing. These profiles come in various shapes and sizes, each designed for specific applications. Common types include:

- Corner profiles

- Duct and double-duct profiles

- Square and round tubes and pipes

- T-tracks

- U channels

- Z profiles

- Flat, round, and square bars

You will find these profiles used in components like borders with attachments, water deflectors, and automobile trim. They also serve critical functions in body structures, such as vehicle frames and chassis components.

The design of aluminum extrusion profiles significantly influences vehicle structural integrity. By transitioning to these profiles, manufacturers achieve substantial weight reduction. This reduction is essential for enhancing vehicle performance and fuel efficiency. Moreover, aluminum’s durability and sustainability contribute to the overall strength of vehicles.

Understanding the behavior of aluminum alloys under stress is crucial for safety. Advanced damage models, like the Gurson damage model, help simulate crash scenarios accurately. This simulation ensures that aluminum components maintain their integrity during impacts, ultimately improving vehicle safety.

Incorporating aluminum extrusion profiles into automotive design not only enhances efficiency but also fortifies safety measures, making them indispensable in modern vehicles.

Benefits of Aluminum Extrusions in Automotive Design

Aluminum extrusions offer numerous advantages in automotive design, making them a preferred choice for manufacturers. Here are some key benefits:

-

Weight Reduction: Aluminum extrusions are generally lighter than traditional steel components. This weight reduction leads to improved fuel efficiency and performance. For instance, the introduction of the 2014 Ford F-150, which featured a full aluminum body, resulted in a weight reduction of nearly 700 pounds compared to its 2013 model. This significant decrease not only enhanced fuel efficiency but also contributed to lower CO2 emissions.

-

Design Flexibility: Aluminum extrusions enable the creation of complex shapes and custom profiles tailored to specific automotive applications. This flexibility is crucial for innovative vehicle designs and the incorporation of multifunctional features. You can achieve unique designs that enhance both aesthetics and functionality.

-

Crash Safety: Aluminum extrusions exhibit high energy absorption capabilities, which are essential for crash safety. Their design significantly enhances the crashworthiness of vehicles. Studies show that the behavior of aluminum under axial loading is critical for predicting crash performance. This means that vehicles using aluminum extrusions can better protect occupants during an accident.

-

Sustainability: Aluminum is a more sustainable option compared to traditional materials. The use of aluminum extrusions can lead to significant energy savings over the vehicle’s lifecycle. For every ton of aluminum recycled, you spare nine tons of CO2 emissions. Additionally, lightweight vehicles lead to improved fuel efficiency and reduced carbon emissions.

-

Lifecycle Cost Efficiency: Incorporating aluminum extrusions can reduce the overall lifecycle cost of vehicles. Each pound of aluminum replaces about two pounds of steel, resulting in savings of 3.1 gallons of crude oil and 20 pounds of CO2 over the vehicle’s lifespan. A vehicle with a higher aluminum content experiences a 20% reduction in lifecycle energy consumption, directly contributing to lower operational costs.

Here’s a comparison of aluminum extrusions and traditional steel components:

| Aspect | Aluminum Extrusions | Traditional Steel Components |

|---|---|---|

| Weight | Generally lighter, but requires thicker parts for safety | Thinner parts possible due to higher tensile strength |

| Design Flexibility | Offers design flexibility but may require larger geometries | More limited design flexibility |

| Cost | 2-3 times higher per kilogram than steel | Generally lower cost |

| Sustainability | More sustainable options available | Less sustainable compared to aluminum |

Applications of Aluminum Extrusions in Vehicles

Aluminum extrusions find extensive applications in various vehicle components, enhancing both efficiency and safety. Here are some key areas where you can see the impact of aluminum extrusions:

-

Engine Components:

- Aluminum extrusions are commonly used in engine parts such as cylinder heads, pistons, and engine blocks. Their lightweight nature helps improve fuel efficiency while maintaining strength.

-

Chassis and Body Structures:

- You will find aluminum extrusions in car doors, hoods, and roofs. These components reduce vehicle weight and enhance fuel efficiency. They also absorb impact energy, which improves safety during collisions. The high strength of aluminum extrusions contributes to better handling and stability in vehicles.

-

Suspension Systems:

- Suspension components like control arms and knuckles benefit from aluminum extrusions. Their lightweight design enhances overall vehicle performance and efficiency.

-

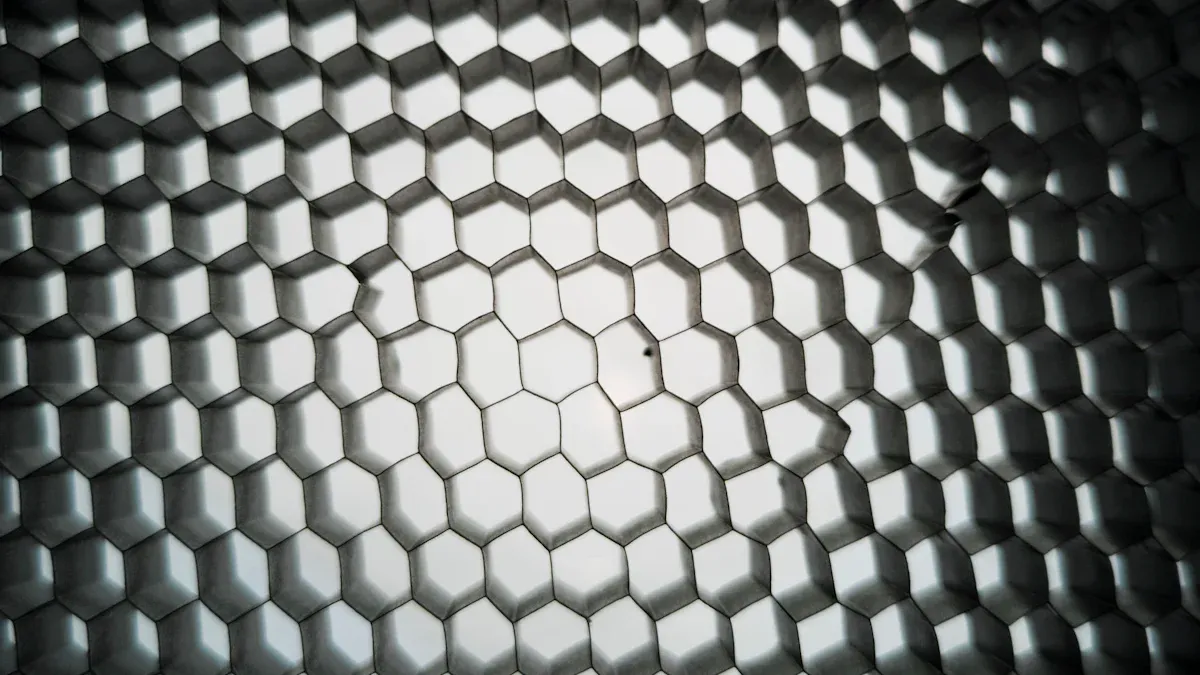

Battery Enclosures for Electric Vehicles:

- Aluminum extrusions play a crucial role in electric vehicle battery enclosures. They provide structural integrity, safeguarding the battery during crashes. Additionally, aluminum’s thermal conductivity helps manage heat, ensuring optimal battery performance.

Benefit Description Structural Integrity Safeguards the battery during crashes. Thermal Management Dissipates heat generated during charging and operation. Lightweight Protection Offsets the battery’s weight, improving overall vehicle efficiency. -

Crash Management Systems:

- Aluminum extrusions are integral to automotive crash management systems. They absorb or deflect energy during collisions, protecting the passenger compartment.

Application Area Description Energy Absorption Designed to absorb or deflect energy during collisions to protect the passenger compartment. Load Path Design Engineered to create a load path that directs impact forces away from the passenger area. Bumper Systems Extruded aluminum bumper beams enhance crash safety with superior energy absorption compared to steel. Crush Cans Deform upon impact, absorbing crash energy without cracking, further protecting passengers. -

Door and Window Frames:

-

Aluminum extrusions provide solid, leak-proof frames that last the lifetime of the vehicle. Their resistance to corrosion contributes to durability and low maintenance needs.

-

The lightweight nature of aluminum enhances vehicle efficiency and performance.

-

Aluminum is infinitely recyclable, making it a sustainable choice for automotive applications.

-

-

Roof Structures:

-

Roof headers made from aluminum extrusions enhance the structural integrity of vehicles, particularly in rollover scenarios. They stabilize the windshield and protect occupants during crashes.

-

Custom aluminum extrusions provide a strong defense in crash management due to their higher impact absorption compared to steel.

-

-

Heat Exchangers and Cooling Systems:

- Aluminum extrusions are also used in automotive heat exchangers. Their lightweight nature and excellent thermal conductivity make them ideal for cooling systems.

Advantage Description Lightweight Significantly lighter than other metals, crucial for automotive applications. Excellent Thermal Conductivity Conducts heat and cold better than many metals, ideal for heat exchangers. Corrosion Resistance Natural oxide layer provides excellent resistance to corrosion. Cost-Effectiveness More affordable than copper, reducing production costs in large-scale manufacturing. Design Flexibility Malleability allows for innovative designs, enhancing performance and efficiency. Sustainability 100% recyclable, requiring less energy to recycle than to produce new aluminum.

Real-World Examples of Impact

Aluminum extrusions have made a significant impact on vehicle efficiency and safety across various models. Here are some notable examples:

| Vehicle Model | Aluminum Extrusion Use | Efficiency Improvement Details |

|---|---|---|

| 2021 Ford Mustang Mach-E | Aluminum extruded bumper and crash cans | Best business case despite heavier weight |

| 2024 Cadillac Lyriq | Front bumper reinforcement beam, rocker | Lightweight design improves energy absorption |

| 2024 Rivian R1T | Rear bumper support reinforcement bar | Similar extrusion assembly enhances crash performance |

| 2019 Acura RDX | Aluminum extruded bumpers on steel-intensive structure | Enhances crash management and overall vehicle safety |

| Honda Civic, CRV, MDX | Lightweight bumper reinforcement beams | Contributes to overall vehicle efficiency |

Automotive brands have effectively utilized extruded aluminum rails to enhance crash safety. These rails, made from high-strength aluminum alloys, absorb higher strain energy during impacts. This design minimizes passenger intrusion and creates effective crumple zones. The energy absorption capacity of aluminum increases with thickness, allowing manufacturers to maintain safety standards while achieving a lightweight design.

In commercial vehicles, the shift to aluminum has led to impressive fuel savings. A steel truck body can weigh up to 1,500 lbs more than its aluminum counterpart. This weight difference results in improved fuel efficiency, reducing diesel consumption by 15–25%. Long-haul fleets have reported annual fuel savings of 800–1,200 gallons per truck when transitioning to aluminum.

These real-world examples illustrate how aluminum extrusions not only enhance vehicle performance but also significantly improve safety ratings and fuel efficiency.

Aluminum extrusions are vital for the future of automotive design. They enhance efficiency and safety, making vehicles lighter and more robust. The automotive aluminum extrusion market is projected to grow at a CAGR of 8.23% from 2024 to 2034, exceeding USD 200.30 billion by 2034. This growth stems from the rising demand for lightweight and electric vehicles.

By emphasizing aluminum’s benefits, you can drive further advancements in the automotive industry, paving the way for innovative vehicle solutions.

FAQ

What are the main advantages of using aluminum extrusions in vehicles?

Aluminum extrusions reduce weight, enhance fuel efficiency, improve crash safety, and offer design flexibility for innovative automotive applications.

How do aluminum extrusions contribute to vehicle safety?

Aluminum extrusions absorb impact energy during collisions, improving crashworthiness and protecting occupants through effective crumple zones.

Are aluminum extrusions environmentally friendly?

Yes, aluminum is highly recyclable, requiring less energy to recycle than to produce new aluminum, making it a sustainable choice for automotive applications.