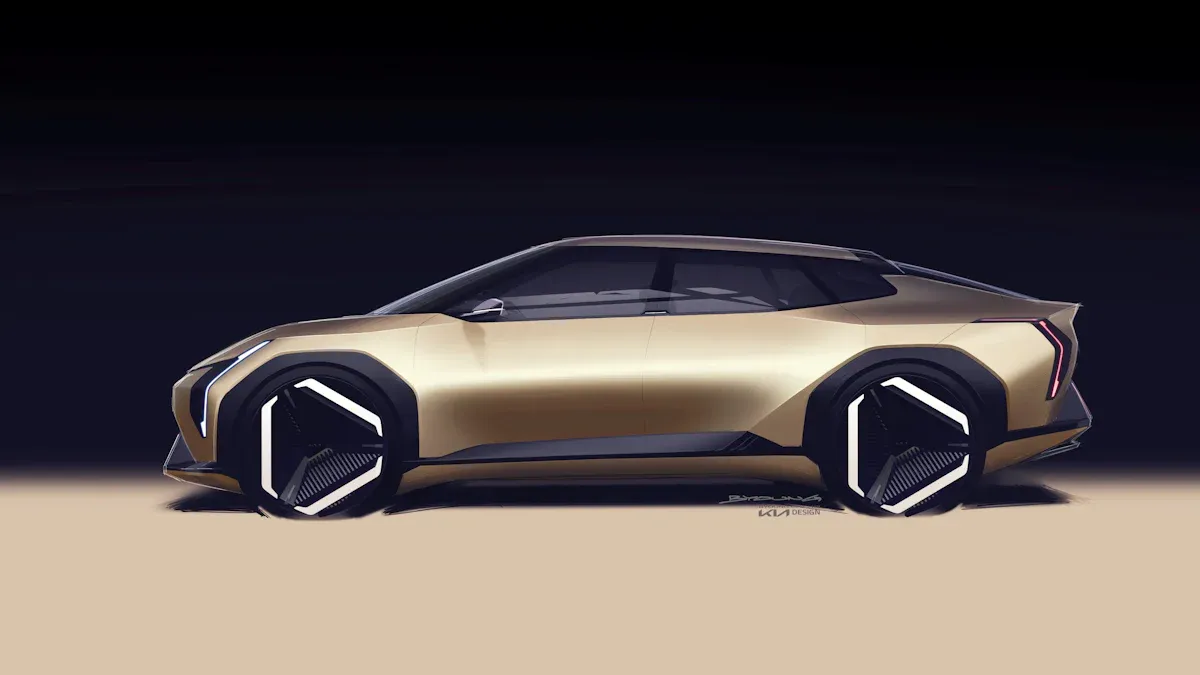

Aluminum extrusion profiles are changing the game in automotive manufacturing. You benefit from enhanced design flexibility, allowing for innovative vehicle structures. The lightweight properties of these profiles help reduce overall vehicle weight, which improves fuel efficiency and lowers emissions. The automotive aluminum extrusion market was valued at USD 76.58 billion in 2023 and is projected to reach USD 147.08 billion by 2031. This growth reflects a strong shift towards sustainable practices and the increasing demand for electric vehicles, which rely on lightweight materials for optimal performance.

Key Takeaways

- Aluminum extrusion profiles reduce vehicle weight, improving fuel efficiency and lowering emissions. This can lead to an average weight reduction of 35 pounds per vehicle.

- These profiles enhance vehicle safety by absorbing impact energy during collisions. Their design allows for better deformation, which improves crashworthiness.

- Aluminum extrusion profiles are cost-effective in the long run. Although initial tooling costs may be higher, they often result in lower maintenance costs and better durability.

- Using aluminum supports sustainability in the automotive industry. It can contain up to 75% recycled content and recycling aluminum uses 95% less energy than producing new aluminum.

- Aluminum profiles are versatile in automotive design, suitable for structural components, aesthetic features, and thermal management systems, enhancing both functionality and style.

Advantages of Aluminum Extrusion Profiles

Lightweight Properties

Aluminum extrusion profiles significantly reduce vehicle weight, which directly impacts performance and efficiency. By using these profiles, you can achieve an average weight reduction of approximately 35 pounds per vehicle. This reduction is projected to increase to nearly 45 pounds per vehicle by 2025. Such weight savings lead to improved fuel efficiency and lower emissions, making your vehicles more environmentally friendly. In fact, aluminum utility bodies can result in a 35% reduction in body weight compared to traditional steel counterparts. This lightweight advantage is crucial as the automotive industry shifts towards more sustainable practices.

Enhanced Strength and Durability

You might be surprised to learn that aluminum extrusion profiles not only offer lightweight benefits but also provide enhanced strength and durability. The mechanical properties of aluminum contribute to vehicle safety standards. For instance, the tensile strength of aluminum extrusion profiles ranges from 180-220 MPa, while yield strength can reach 90-140 MPa. In comparison, traditional steel typically has a tensile strength of 455 MPa and a yield strength of 380 MPa. However, aluminum’s ability to absorb energy during impact makes it a safer choice for vehicle design. The elongation percentage of aluminum, which ranges from 10-25%, allows for better deformation without failure, enhancing overall vehicle safety.

Cost-Effectiveness

When considering manufacturing costs, aluminum extrusion profiles present a competitive option. While the initial tooling costs for aluminum may be higher due to die development and special coatings, the long-term benefits often outweigh these expenses. For example, the maintenance costs associated with vehicles using aluminum profiles tend to be lower over time. A typical life cycle cost analysis reveals that aluminum vehicles require less frequent repairs and maintenance compared to their steel counterparts.

| Material Type | Cost Factors | Comparison to Aluminum |

|---|---|---|

| Aluminum | Higher tooling costs, die development, special coatings | Generally higher than steel due to tooling and material prices |

| Steel | Lower tooling costs, faster stamping rates | More cost-effective than aluminum in many applications |

| Composite | Varies based on application | Cost-effectiveness can be competitive depending on the process |

Sustainability Benefits

Aluminum extrusion profiles play a crucial role in enhancing sustainability within the automotive industry. Their lightweight properties not only improve fuel efficiency but also significantly reduce emissions during vehicle operation. By choosing aluminum, you can help your vehicles meet stringent Environmental, Social, and Governance (ESG) targets and regulations. Here are some key sustainability benefits of using aluminum extrusion profiles:

- Energy Consumption: The production of aluminum is energy-intensive, which can affect emissions. However, the lightweight nature of aluminum helps improve fuel efficiency, leading to lower operational emissions.

- Recycling Benefits: One of the most significant advantages of aluminum is its recyclability. Recycling aluminum uses 95% less energy than producing new aluminum from raw materials. This process leads to a substantial reduction in emissions.

- Material Selection: The choice of aluminum influences vehicle mass, energy consumption, and overall carbon dioxide equivalent (CO2e) impact. By selecting aluminum extrusion profiles, you contribute to a more sustainable manufacturing process.

- Long-term Supply Security: Utilizing aluminum enhances cost predictability and sustainability. This stability is essential as the automotive industry faces fluctuating material costs and supply chain challenges.

The following table summarizes how aluminum extrusion profiles impact the carbon footprint of automotive manufacturing:

| Aspect | Impact on Carbon Footprint |

|---|---|

| Energy Consumption | Aluminum production is energy-intensive, affecting emissions. |

| Lightweight Properties | Improves fuel efficiency, reducing operational emissions. |

| Recycling Benefits | Recycling aluminum uses 95% less energy than primary production, leading to lower emissions. |

| Material Selection | Influences vehicle mass, energy consumption, and CO2e impact. |

| Long-term Supply Security | Enhances cost predictability and sustainability. |

Additionally, up to 75% of the aluminum used in extrusion profiles for automotive applications can come from post-consumer recycled content. This high recycling rate not only conserves resources but also minimizes the environmental impact associated with raw material extraction.

By integrating aluminum extrusion profiles into your automotive designs, you actively contribute to a more sustainable future. The combination of lightweight properties, energy efficiency, and recycling capabilities positions aluminum as a leading material in the quest for greener automotive solutions.

Applications of Aluminum Extrusion Profiles in Automotive Design

Aluminum extrusion profiles play a vital role in modern automotive design, enhancing both functionality and aesthetics. Their versatility allows you to implement them in various applications, from structural components to intricate aesthetic features.

Structural Components

You can find aluminum extrusion profiles in several critical structural components of vehicles. These profiles provide the necessary strength while significantly reducing weight. Common applications include:

- Chassis Components: These profiles offer structural integrity, ensuring that the vehicle remains robust yet lightweight.

- Crash Structures: They absorb impact energy, enhancing passenger safety during collisions.

- Battery Enclosures: In electric vehicles, these profiles protect sensitive components, ensuring their longevity and reliability.

- Body Frames: Essential for maintaining the vehicle’s overall structure.

- Chassis Parts: Key components that support the vehicle’s weight and stability.

- Crash Management Systems: Important for safety, these systems utilize aluminum profiles to minimize injury during accidents.

Aluminum extrusion profiles improve crashworthiness in automotive structural components. For instance, using these profiles can lead to a 4.74% reduction in peak load during impacts. Additionally, they can increase energy absorption by 7%, enhancing overall vehicle safety.

| Finding | Description |

|---|---|

| Peak Load Reduction | Up to 4.74% reduction in peak load (Pmax) with discontinuities. |

| Energy Absorption Increase | 7% increase in energy absorption (Ea) observed with discontinuities. |

| Crush Force Efficiency | 12.69% increase in crush force efficiency (CFE) noted with mechanical discontinuities. |

Aesthetic Features

Aluminum extrusion profiles also contribute significantly to the aesthetic appeal of vehicles. Their design advantages allow for a blend of functionality and style. Key benefits include:

| Advantage | Description |

|---|---|

| Strength-to-weight ratio | Aluminum is lighter than steel while maintaining high structural strength, ideal for automotive applications. |

| Design flexibility | Custom extrusion allows for intricate and complex profiles, enhancing both functionality and aesthetics. |

| Corrosion resistance | Aluminum’s natural resistance to corrosion makes it suitable for automotive applications exposed to various environments. |

You can customize vehicle exteriors and interiors using aluminum extrusion profiles. This customization includes body structures, chassis components, and interior parts. For example, you can design tailored dashboard frames and seat brackets that enhance both aesthetics and functionality.

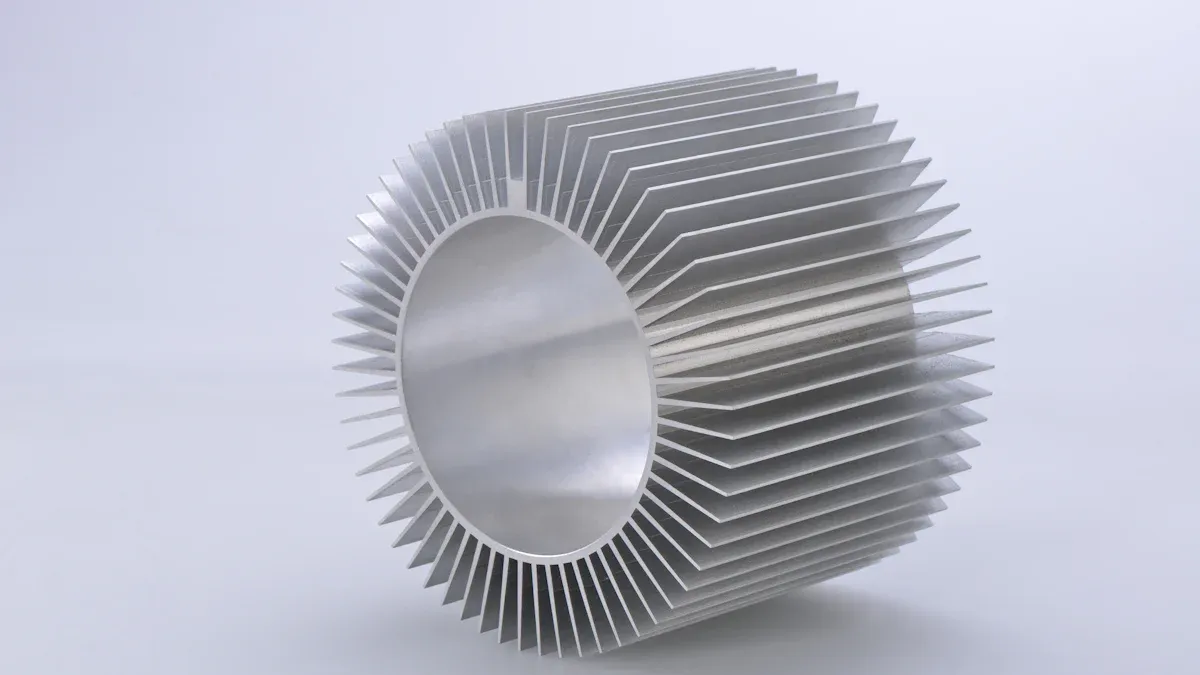

Heat Exchangers and Radiators

In automotive cooling systems, aluminum extrusion profiles excel in efficiency. They are engineered for exceptional thermal performance, ensuring optimal heat exchange. Key features include:

| Feature | Description |

|---|---|

| Thermal Performance | Engineered for exceptional thermal performance, ensuring optimal heat exchange. |

| Durability | Focus on durability for long-lasting use in various applications. |

| Lightweight Design | Ideal for a wide range of radiator configurations due to lightweight properties. |

Aluminum alloys, such as 6061 and 6063, are known for their high thermal conductivity. This property is essential for effective heat management in automotive cooling systems. Their lightweight nature and versatility in design further enhance their suitability for these applications.

By integrating aluminum extrusion profiles into your automotive designs, you not only improve structural integrity and aesthetics but also enhance thermal management, making your vehicles more efficient and appealing.

Innovations in Electric Vehicles Using Aluminum Extrusion Profiles

Battery Housing Solutions

You can significantly enhance the safety and efficiency of electric vehicles by utilizing aluminum extrusion profiles for battery housings. These profiles offer several key benefits:

- Durability: They ensure battery packs are well-protected against impacts.

- Lightweight: This contributes to a significant weight reduction, crucial for electric vehicle efficiency.

- Regulatory Compliance: Aluminum profiles meet safety standards for battery enclosures.

- Simplified Assembly: They facilitate easier construction of battery modules.

- Electromagnetic Shielding: This protects electronic components from interference.

- Energy Absorption: Aluminum performs better in crash scenarios compared to other materials.

By using aluminum, you achieve a weight reduction of up to 50% compared to traditional steel battery enclosures. This mass savings improves the vehicle’s range and energy efficiency.

Lightweight Chassis Design

Aluminum extrusion profiles play a vital role in designing lightweight chassis for electric vehicles. By replacing steel with aluminum, you can achieve a weight reduction of 25-30%. This reduction enhances acceleration and energy efficiency. The structural integrity of aluminum ensures that the battery remains safeguarded during crashes, enhancing overall chassis strength.

| Benefit | Description |

|---|---|

| Structural integrity | Safeguards the battery during crashes, enhancing overall chassis strength. |

| Thermal management | Dissipates heat generated during charging and operation, crucial for battery safety. |

| Lightweight protection | Offsets the battery’s weight, improving vehicle efficiency and range. |

| Customization | Integrated channels for cooling and wiring reduce design complexity and component count. |

| Crash management systems | Engineered to deform predictably under impact, absorbing energy and protecting passengers. |

Thermal Management Systems

Effective thermal management is essential for the performance and longevity of electric vehicles. Aluminum extrusion profiles excel in this area due to their natural thermal conductivity. You can use custom aluminum extrusions in battery housings and cooling plates to enhance thermal management.

- High thermal dissipation efficiency: This improves battery life and performance.

- Lightweight nature: It contributes to overall vehicle efficiency, especially during high-demand situations.

- Serpentine cooling tubes: Made from extruded aluminum, these optimize coolant flow, maintaining ideal temperatures for battery cells.

By integrating aluminum extrusion profiles into your thermal management systems, you ensure that your electric vehicle operates efficiently and reliably.

Comparison of Aluminum Extrusion Profiles with Traditional Materials

Steel vs. Aluminum

When comparing steel and aluminum, you will notice significant differences in mechanical properties and applications. Here are some key points to consider:

- Tensile Strength: Steel ranges from 400 MPa to 500 MPa, while aluminum is around 90 MPa. This indicates that steel can withstand greater tension.

- Compressive Strength: Steel outperforms aluminum, bearing higher loads without significant deformation.

- Yield Strength: Steel’s yield strength is about 250 MPa, compared to aluminum’s 40 MPa, showcasing steel’s strength advantage.

While aluminum is lighter, steel’s higher strength allows for thinner designs, optimizing load-bearing capabilities. However, aluminum’s lightweight nature makes it suitable for applications where weight reduction is critical.

Composite Materials

Composite materials offer unique advantages in automotive applications. They combine different materials to achieve superior performance. Here’s how they compare to aluminum extrusion profiles:

- Weight: Composites can be lighter than aluminum, depending on the specific materials used.

- Strength: Some composites exhibit high strength-to-weight ratios, making them competitive with aluminum in certain applications.

- Cost: Generally, composites can be more expensive than aluminum due to complex manufacturing processes.

Aluminum extrusion profiles remain a popular choice due to their balance of cost, weight, and strength, making them ideal for various automotive applications.

Performance Metrics

When evaluating performance metrics, aluminum extrusion profiles excel in several areas:

- Crash Test Ratings: Aluminum alloys, particularly those in the 5xxx series, are known for their high strength and low density. This combination enhances crash performance.

- Weight Savings: Aluminum profiles can achieve weight savings of up to 25% compared to traditional steel structures. This reduction contributes to improved fuel efficiency and lower emissions.

- Energy Absorption: Aluminum can absorb energy effectively during crashes, enhancing passenger safety.

Future Trends and Challenges for Aluminum Extrusion Profiles

Advancements in Extrusion Technology

You can expect significant advancements in aluminum extrusion technology that will shape the automotive industry. Here are some key developments to watch:

- Reducing Carbon Emissions: Manufacturers are focusing on minimizing carbon emissions throughout the aluminum production value stream. This shift promotes sustainability and aligns with global environmental goals.

- Higher Strength Alloys: The development of higher strength 6000 series aluminum alloys enhances durability in automotive applications. These alloys provide better performance while maintaining lightweight characteristics.

- Micro-Extrusion Capabilities: The introduction of micro-extrusion allows for the production of ultra-thin profiles. This capability is essential for creating components in electric vehicles, where space and weight savings are critical.

Market Demand and Supply Chain Issues

The automotive aluminum extruded profiles market faces challenges due to fluctuations in raw material prices. You may notice that the costs of aluminum ingots and billets are influenced by global supply chain disruptions, energy prices, and geopolitical tensions. These factors complicate your ability to manage production costs effectively. Additionally, labor shortages and transportation bottlenecks hinder aluminum extruders from meeting just-in-time delivery requirements. As a result, you might experience delays or increased costs in sourcing aluminum profiles for your automotive projects.

Regulatory and Environmental Considerations

Environmental regulations play a crucial role in the adoption of aluminum extrusion profiles in the auto industry. Here are some key influences:

- Regulations promote the use of lightweight materials to meet emission standards.

- Stricter fuel economy standards and electrification mandates incentivize the adoption of aluminum profiles.

- Regulations around recyclability and circular economy principles drive innovation in aluminum recycling processes.

- The transition towards electric vehicles (EVs) is accelerated by regulatory pressures, increasing the demand for aluminum components.

By staying informed about these trends and challenges, you can better navigate the evolving landscape of aluminum extrusion profiles in the automotive sector.

The integration of aluminum extrusion profiles significantly transforms the automotive industry. You benefit from lighter vehicles that enhance fuel efficiency and reduce emissions. These profiles also support innovative designs, allowing you to create vehicles that meet modern sustainability standards. As the industry evolves, embracing aluminum extrusion profiles will be crucial for staying competitive and environmentally responsible.

FAQ

What are aluminum extrusion profiles?

Aluminum extrusion profiles are shapes created by forcing aluminum through a die. This process allows manufacturers to produce complex shapes that are lightweight, strong, and versatile for various automotive applications.

How do aluminum extrusion profiles improve vehicle safety?

These profiles absorb impact energy during collisions, enhancing passenger safety. Their design allows for better deformation without failure, which contributes to improved crashworthiness in vehicles.

Are aluminum extrusion profiles cost-effective?

Yes, while initial tooling costs may be higher, aluminum profiles often lead to lower maintenance costs over time. Their durability and lightweight nature can result in significant savings in fuel efficiency.

What role do aluminum extrusion profiles play in electric vehicles?

In electric vehicles, aluminum extrusion profiles are crucial for battery housings, lightweight chassis designs, and thermal management systems. They enhance safety, efficiency, and overall vehicle performance.

How sustainable are aluminum extrusion profiles?

Aluminum extrusion profiles are highly sustainable. They can contain up to 75% recycled content, and recycling aluminum uses 95% less energy than producing new aluminum, significantly reducing environmental impact.