Precision injection molding plays a vital role in enhancing automotive design. It significantly improves efficiency and performance by creating lightweight parts, like aluminum extrusion profiles, which contribute to better fuel efficiency. Additionally, the production of plastic auto parts through this innovative process minimizes material waste, offering a cost-effective solution that benefits both manufacturers and the environment. Furthermore, the technology can be applied to create specialized components such as rectangle linear drain shower drains and water cooling plate copper tubes, showcasing its versatility in various applications.

Key Takeaways

- Precision injection molding enhances automotive design by creating lightweight parts, improving fuel efficiency, and reducing material waste.

- This process offers exceptional design flexibility, allowing for complex shapes and the integration of different materials in a single component.

- Adopting precision injection molding leads to significant cost savings by minimizing waste and optimizing production processes, making it essential for competitive manufacturing.

Benefits of Precision Injection Molding

Precision injection molding offers numerous advantages that significantly enhance automotive design. By leveraging this innovative process, you can achieve remarkable improvements in design flexibility, material efficiency, and cost-effectiveness.

Design Flexibility

One of the standout benefits of precision injection molding is its exceptional design flexibility. This process allows you to create intricate and complex geometries that other manufacturing methods struggle to achieve. Here are some key aspects of design flexibility:

- Multi-shot molding and overmolding enable you to combine hard and soft materials in a single component. This enhances functionality and comfort while reducing assembly steps.

- The ability to produce complex shapes, such as undercuts and thin walls, opens up a world of design possibilities for automotive components.

- Advanced molding techniques support the integration of various materials, allowing for innovative designs that meet specific performance requirements.

With precision injection molding, you can push the boundaries of automotive design, creating components that are not only functional but also aesthetically pleasing.

Material Efficiency

Material efficiency is another critical advantage of precision injection molding. This process minimizes waste and maximizes the use of raw materials, which is essential in today’s environmentally conscious market. Consider the following points:

- Companies typically experience a reduction of 25–40% in waste and defects when utilizing precision molding. This means you can produce more parts with less material.

- On average, 98% of the purchased raw material is utilized in final products through this method. This high level of efficiency translates to significant cost savings.

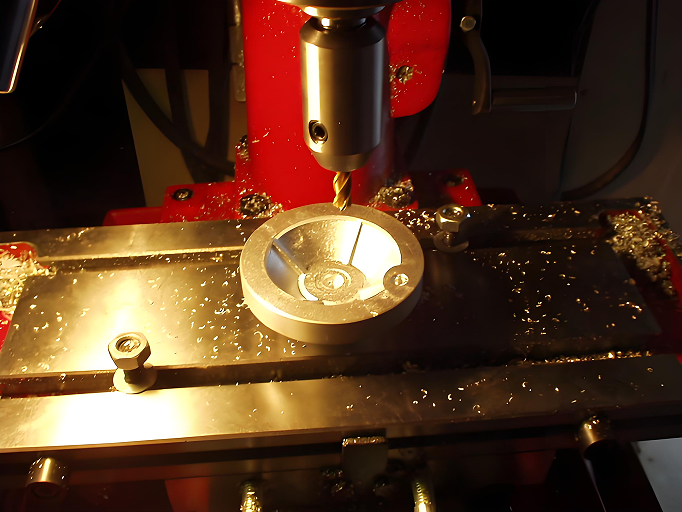

- The process involves melting plastic resin, injecting it into a precision-machined mold, and cooling it to form complex automotive parts. This ensures that you achieve high levels of detail and accuracy, crucial for intricate components like dashboards and door panels.

By adopting precision injection molding, you not only enhance the quality of your automotive parts but also contribute to sustainability efforts by reducing material waste.

Cost-Effectiveness

Cost-effectiveness is a vital consideration for any automotive manufacturer. Precision injection molding excels in this area by minimizing material waste and optimizing production processes. Here’s how:

- High-volume production lowers per-unit costs by spreading initial setup costs over more parts. This makes it economical for large batches.

- Advanced technologies like CAD enhance the design process, optimizing material usage and reducing overall production costs.

- The technique allows for efficient use of materials, leading to significant material savings.

Additionally, the long-term benefits of using precision injection molding include high efficiency and speed, high-quality results, and economies of scale. These factors collectively contribute to a more cost-effective manufacturing process, ensuring that you remain competitive in the automotive industry.

By embracing precision injection molding, you can achieve a balance of quality, efficiency, and cost savings, making it an indispensable tool in modern automotive design.

Applications in Automotive Components

Precision injection molding plays a crucial role in the production of various automotive components. This process enhances the performance, durability, and aesthetic appeal of parts across different areas of vehicle design. Let’s explore how precision injection molding applies to engine parts, interior components, and exterior panels.

Engine Parts

Engine components benefit significantly from precision injection molding. This method allows you to produce parts that are lightweight yet durable, which is essential for enhancing vehicle performance and fuel efficiency. Commonly produced engine components include:

- Air intake manifolds

- Valve covers

- Sensor housings

- Electrical connectors

Using materials like polyamide (PA) and polyphenylene sulfide (PPS) ensures that these components withstand high temperatures and harsh operating conditions. The advantages of using plastic for engine parts include:

- Weight Reduction: Lightweight components improve overall vehicle performance.

- Durability: Precision injection molding enhances the strength and reliability of parts, making them suitable replacements for traditional metal components.

| Benefit | Description |

|---|---|

| High-performance materials | Utilizes thermoplastics that withstand harsh environments, enhancing strength and reliability. |

| Complex designs | Allows for the creation of intricate components with tight tolerances, ensuring consistent quality. |

| Replacement of metal components | Capable of producing parts that can replace metal, contributing to overall durability. |

Interior Components

Precision injection molding also revolutionizes the production of interior automotive components. This process allows for the creation of complex geometries and integrated designs that enhance both functionality and aesthetics. Key interior components produced through this method include:

- Dashboards

- Door panels

- Clips and fasteners

The benefits of injection molding for these components are substantial:

| Component Type | Benefits of Injection Molding |

|---|---|

| Dashboards | Complex shapes, durability, aesthetic appeal |

| Door Panels | High repeatability, strength |

| Clips and Fasteners | Precision, consistency in production |

Moreover, precision injection molding enables you to achieve smooth finishes and custom colors that match the vehicle’s design. This capability enhances the visual appeal of parts like custom trims and gear knobs, making them not only functional but also attractive.

Exterior Panels

When it comes to exterior panels, precision injection molding offers remarkable advantages. This process allows for the production of lightweight components that improve aerodynamic efficiency and visual appeal. Key benefits include:

- High accuracy in producing complex shapes, essential for intricate automotive components.

- The ability to create lightweight exterior panels that enhance overall vehicle performance.

- Aesthetic enhancements through smooth finishes and intricate details.

The versatility of injection molding supports the crafting of components that meet both functional and aesthetic expectations. This ensures that exterior panels not only perform well but also contribute to the vehicle’s overall design.

Case Studies of Successful Implementations

Ningbo Tiehou Auto Parts Co., Ltd. Innovations

Ningbo Tiehou Auto Parts Co., Ltd. exemplifies innovation in precision injection molding within the automotive sector. Established in 2018, this company has over 20 years of experience in the field. Their commitment to design and manufacturing excellence has led to the development of high-quality components for various automotive applications.

Their focus on sustainability and customer-oriented solutions has resulted in significant advancements. For instance, they have successfully integrated multi-shot molding techniques to produce complex parts that combine different materials. This innovation not only enhances functionality but also reduces assembly time, making the manufacturing process more efficient.

Aluminum Extrusion Profiles in Action

Aluminum extrusion profiles play a crucial role in reducing vehicle weight while maintaining strength. These profiles have high strength-to-weight ratios, making them ideal for critical vehicle components. Here are some key benefits:

- Converting a vehicle’s body-in-white (BIW) structure from steel to aluminum can lead to a weight reduction of approximately 40% in modified parts.

- The unique properties of aluminum, such as heat conductivity and strength, enhance its application in various vehicle components.

- Lightweight components like bumper beams and frame parts contribute to improved fuel efficiency and overall vehicle performance.

By utilizing aluminum extrusion profiles, manufacturers can achieve significant weight savings, which is essential for modern automotive design.

Future Trends in Automotive Manufacturing

As the automotive industry evolves, precision injection molding continues to play a pivotal role in shaping future manufacturing trends. You can expect significant advancements in materials and the integration of cutting-edge technologies to enhance production efficiency and sustainability.

Advancements in Materials

The automotive sector is witnessing a surge in innovative materials that optimize performance and reduce environmental impact. Here are some key developments:

- Hybrid Components: These blend plastic and metal, optimizing strength while minimizing weight.

- Carbon Fiber Composites: They provide a lightweight solution that enhances fuel efficiency and reduces emissions.

- Advanced High-Strength Steels (AHSS): These materials offer superior strength, allowing for weight reduction without sacrificing performance.

- Bio-based and Recycled Plastics: These eco-friendly alternatives help minimize waste and production costs.

The market for continuous fiber-reinforced thermoplastics is projected to grow significantly, reflecting a strong demand for lighter materials that meet stringent environmental regulations.

Integration with Other Technologies

The integration of advanced technologies is transforming precision injection molding. You can expect to see:

- Automation: Increased automation streamlines production, enhancing accuracy and reducing labor costs.

- Artificial Intelligence (AI): AI optimizes manufacturing processes, improving quality and reducing waste. It utilizes high-frequency sensor data for defect prediction and process control.

- Industry 4.0 Principles: These principles enhance manufacturing processes, ensuring that you achieve precision in automotive design.

| Technology | Impact |

|---|---|

| Automation | Streamlines production, improves accuracy, and reduces labor costs. |

| AI | Revolutionizes precision injection molding, enhancing efficiency and quality. |

| Industry 4.0 | Applies smart technologies to improve manufacturing processes in automotive design. |

By embracing these advancements, you can enhance the efficiency and sustainability of automotive manufacturing, positioning your designs for future success.

Precision injection molding is essential for modern automotive design. It enables you to create lightweight components, such as aluminum extrusion profiles, that enhance vehicle performance. This process also supports sustainability by optimizing material use and reducing carbon emissions. By following detailed design guidelines, you can ensure the quality and efficiency of molded parts, preventing manufacturing failures and maintaining structural integrity.

| Benefit | Description |

|---|---|

| Sustainability | Cutting-edge technologies in injection molding address environmental challenges through sustainable materials and efficient processes. |

| Reduced Waste | Injection molding minimizes waste material, using only the amount of plastic needed for the final product. |

| Energy Efficiency | Modern machines are designed for energy conservation, significantly reducing operational costs. |

FAQ

What is precision injection molding?

Precision injection molding is a manufacturing process that creates complex plastic parts with high accuracy and minimal waste.

How does precision injection molding improve fuel efficiency?

By producing lightweight components, precision injection molding reduces vehicle weight, leading to improved fuel efficiency and performance.

What materials are commonly used in precision injection molding for automotive parts?

Common materials include polyamide (PA), polyphenylene sulfide (PPS), and various thermoplastics that offer durability and heat resistance.