OEM buyers increasingly choose aluminum extrusion profiles due to their unique advantages in custom tooling and plastic injection projects. The rising demand for lightweight and durable materials drives this trend, especially in applications like bathroom gate clamps and handles bathroom furniture pulls. Regulatory bodies tighten emissions caps, compelling you to adopt eco-friendly materials. Aluminum extrusion profiles offer versatility and cost efficiency that meet modern manufacturing needs.

Key Takeaways

- Aluminum extrusion profiles are lightweight yet strong, making them ideal for applications in industries like automotive and aerospace.

- These profiles resist corrosion better than steel, reducing maintenance costs and extending the lifespan of components.

- Aluminum extrusions offer design flexibility, allowing for complex shapes and features that enhance efficiency and aesthetics.

Advantages of Aluminum Extrusion Profiles

Lightweight and Strong

Aluminum extrusion profiles offer an impressive strength-to-weight ratio, making them ideal for various applications. While steel is technically stronger, aluminum’s lighter weight allows for easier handling and installation. This characteristic is particularly beneficial in industries like automotive and aerospace, where reducing weight is crucial. You can leverage aluminum’s favorable properties to enhance your designs without compromising structural integrity.

- Key Benefits:

- Aluminum extrusions are lighter than steel, which simplifies transportation and assembly.

- The overall strength of aluminum, when factoring in its lighter weight, makes it a competitive choice in many OEM applications.

- This material’s properties are especially advantageous in sectors where weight reduction is essential.

Corrosion Resistance

One of the standout features of aluminum extrusion profiles is their remarkable ability to resist corrosion. When exposed to air, aluminum forms a protective oxide layer that shields it from environmental damage. This natural defense mechanism is superior to that of steel, which is prone to rust and requires additional protective measures.

- Corrosion Resistance Highlights:

- Aluminum extrusions outperform many commonly used materials in corrosion resistance tests.

- The oxide layer formed on aluminum provides long-lasting protection, reducing maintenance costs and extending the lifespan of components.

- Surface treatments, such as anodizing, can further enhance corrosion resistance, making aluminum an even more attractive option for OEM buyers.

| Treatment Type | Description | Benefits |

|---|---|---|

| Anodizing | Electrochemical process converting aluminum to aluminum oxide (Al₂O₃) | High wear resistance, excellent dimensional stability |

| Passivation | Protects surface against corrosion and provides a base for coatings | Improved corrosion resistance, constant resistance for electrical conductivity |

| Polymer Coatings | Additional protective layer applied over aluminum | Enhanced durability and aesthetic appeal |

Design Flexibility

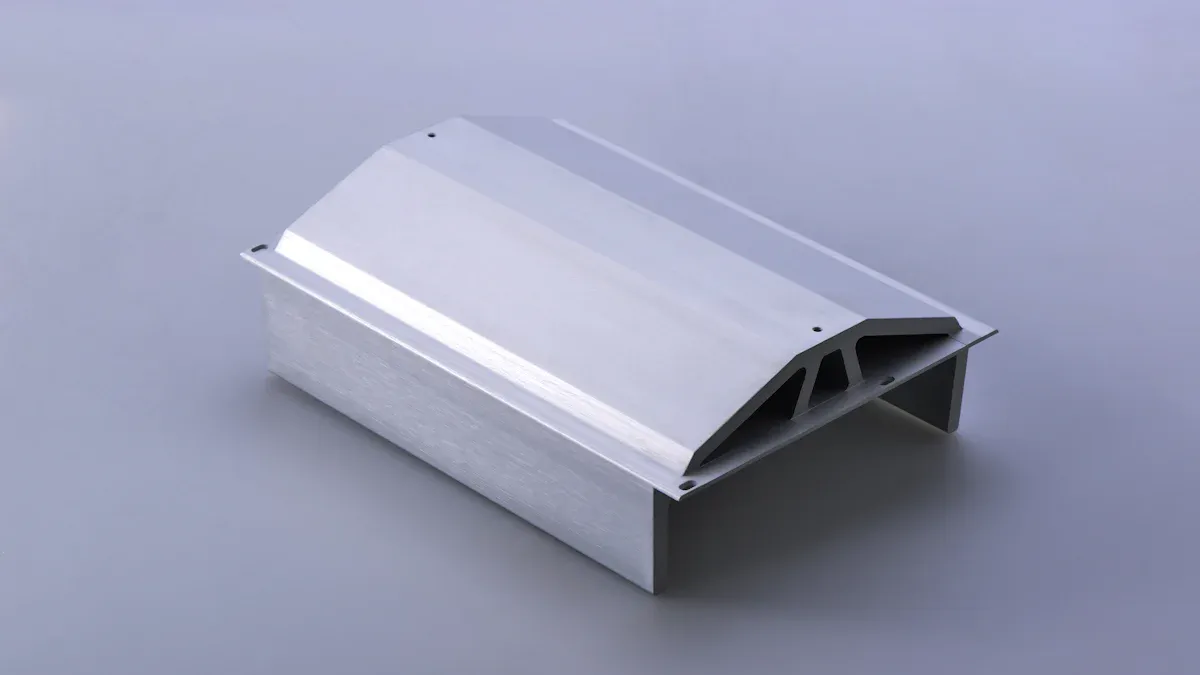

The design flexibility of aluminum extrusion profiles is unmatched. You can create complex shapes and intricate details that are difficult to achieve with other materials. The extrusion process allows for various cross-sectional shapes and contours, enabling you to customize components to meet specific project requirements.

- Design Flexibility Features:

- Aluminum extrusions allow for intricate designs and the incorporation of multiple features into a single profile.

- Complex geometries, such as hollow sections and rounded edges, can be produced without compromising material integrity.

- This adaptability leads to increased efficiency, aesthetics, and personalization in various industries.

The ability to tailor solutions that align with specific functional, structural, and aesthetic needs is crucial for optimizing designs. By utilizing aluminum extrusion profiles, you can enhance strength and assembly while minimizing the need for post-processing, leading to improved production efficiency and cost reduction.

Cost Efficiency of Aluminum Extrusion Profiles

Reduced Material Waste

Aluminum extrusion profiles significantly minimize material waste during production. You can achieve this through several advanced techniques:

- Optimized Die Design: Using sophisticated design software allows you to simulate material flow and predict defects. This approach can reduce scrap rates by up to 30%.

- Advanced Process Control Systems: Real-time monitoring of extrusion parameters can lead to a 10–20% reduction in scrap generation.

- Scrap Minimization Techniques: Implementing precision cutting and automated handling helps minimize offcuts and errors.

- Lean Manufacturing Principles: Applying methodologies like Six Sigma enables you to identify and eliminate waste sources effectively.

- Technologies like AI and Digital Twins: Utilizing AI for defect detection and digital twins for simulating processes can further avoid material waste.

By adopting these strategies, you not only enhance efficiency but also contribute to sustainability in your manufacturing processes.

Lower Production Costs

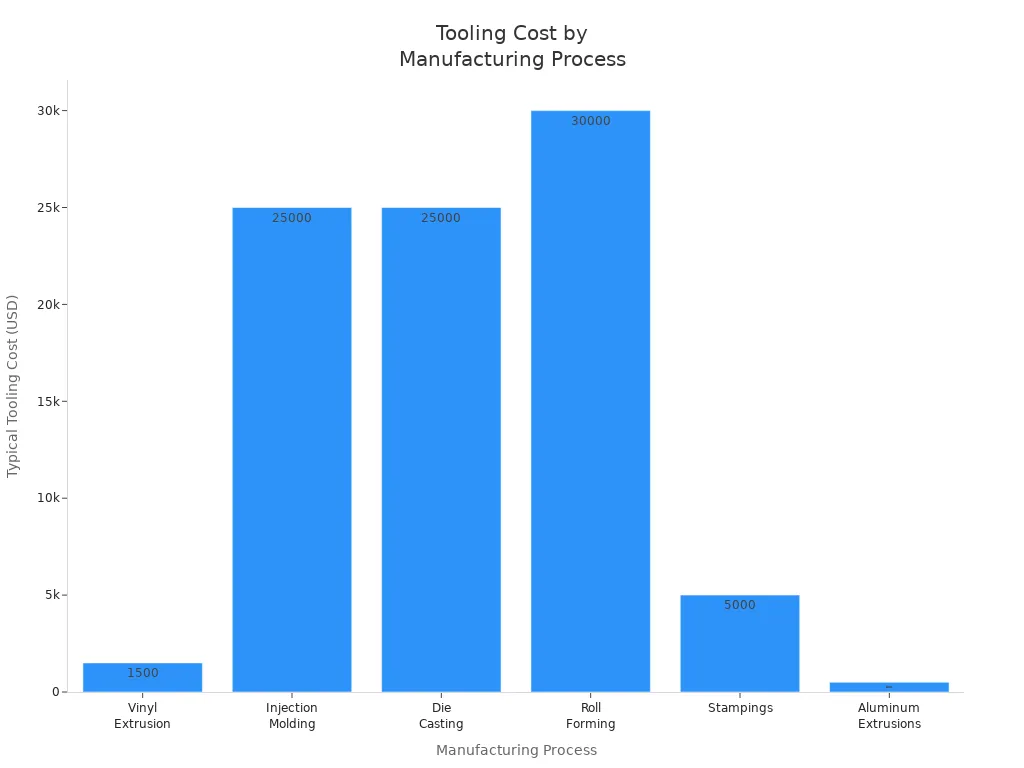

When comparing aluminum extrusion profiles to other manufacturing methods, you will find that aluminum offers substantial cost savings. The tooling costs associated with aluminum extrusion are significantly lower than those for steel or plastic alternatives. Here’s a breakdown of typical tooling costs:

| Manufacturing Process | Typical Tooling Cost |

|---|---|

| Vinyl Extrusion | $1,500+ |

| Injection Molding | $25,000+ |

| Die Casting | $25,000+ |

| Roll Forming | $30,000+ |

| Stampings | $5,000+ |

| Aluminum Extrusions | $500-$5,000 |

This table illustrates how aluminum extrusion profiles can significantly reduce your initial investment in tooling. Additionally, the energy consumption and labor costs associated with aluminum extrusion are competitive. Typically, raw aluminum accounts for 60-70% of total costs, while labor and overheads make up 20-30%, and energy costs range from 10-15%.

Long-Term Savings

Investing in aluminum extrusion profiles leads to long-term savings. Over a five-year period, you will notice lower maintenance and replacement costs compared to galvanized steel and PVC. The durability of aluminum means you will spend less on maintenance, resulting in lower total life cycle costs.

- Aluminum’s longevity reduces the frequency of maintenance.

- Galvanized steel, while initially cheaper, incurs higher maintenance and replacement costs due to its lower durability.

By choosing aluminum extrusion profiles, you not only save on initial costs but also enjoy the benefits of reduced maintenance and enhanced durability over time.

Applications of Aluminum Extrusion Profiles in Custom Tooling and Plastic Injection

Tooling Frameworks

Aluminum extrusion profiles play a vital role in creating robust tooling frameworks. You can leverage their strength-to-weight ratio to enhance structural integrity while keeping the overall weight low. This feature is particularly beneficial in industries such as construction, automotive, and aerospace. Here’s a quick overview of common uses across various sectors:

| Industry | Common Uses |

|---|---|

| Construction | Windows, doors, frames |

| Automotive | Lightweight components for vehicles |

| Aerospace | Structural components |

| Electronics | Heat sinks, enclosures |

| Renewable Energy | Solar panel framing |

The modular design of aluminum profiles allows for easy customization and disassembly, which improves performance and adaptability in tooling frameworks.

Mold Components

In plastic injection projects, aluminum extrusion profiles enhance the lifespan and performance of mold components. Their excellent thermal conductivity facilitates faster heating and cooling cycles, which reduces molding cycle times. This efficiency leads to increased productivity. Additionally, aluminum is easy to machine, which minimizes tool wear and accelerates fabrication. Here are some benefits of using aluminum in mold components:

| Benefit/Limitations | Description |

|---|---|

| Thermal Conductivity | Facilitates faster heating and cooling cycles, reducing molding cycle times and increasing efficiency. |

| Machinability | Easy to machine, reducing tool wear and increasing cutting speed, leading to faster fabrication. |

| Cost-Effectiveness | Typically less expensive than other materials, making it ideal for low-volume production. |

Enhanced Production Speed

Aluminum extrusion profiles significantly impact production speed in custom tooling and plastic injection applications. The extrusion process operates at quick feed rates, ranging from 2 to 20 ft/min, which reduces lead times and costs. Here’s how aluminum profiles enhance production speed:

| Aspect | Impact on Production Speed |

|---|---|

| Extrusion Process Speed | Quick feed rates reduce lead times and costs. |

| Tooling Complexity | Complex profiles can slow down the extrusion process. |

| Cost-Effectiveness | Faster manufacturing leads to lower cost per part. |

By adopting aluminum extrusion profiles, you can achieve minimal raw material wastage while maintaining lightweight designs without sacrificing performance. Companies that have switched to aluminum extrusion have reported up to a 30% increase in production efficiency, showcasing the material’s advantages in modern manufacturing.

The shift towards aluminum extrusions stems from their lightweight, durable, and cost-effective properties. You gain significant advantages by choosing aluminum extrusion profiles for your custom tooling and plastic injection projects. These profiles enhance design flexibility and reduce production costs, leading to improved project outcomes and a competitive edge in the market.

FAQ

What are the main benefits of using aluminum extrusions?

Aluminum extrusions offer lightweight strength, corrosion resistance, and design flexibility, making them ideal for custom tooling and plastic injection projects.

How do aluminum extrusions compare to other materials?

Aluminum extrusions are lighter and more corrosion-resistant than steel, providing cost efficiency and longer lifespan compared to plastic alternatives.

Can aluminum extrusions be customized for specific applications?

Yes, you can customize aluminum extrusions to meet specific project requirements, including complex shapes and sizes tailored to your needs.

Title: Why Are OEM Buyers Turning to Aluminum Extrusions in 2025,

Description: OEM buyers are choosing aluminum extrusion profiles in 2025 for their lightweight, cost-effective, and versatile solutions in custom tooling and injection projects.,

Keywords: Aluminum Extrusion Profile